“Metallurgists are very interested in analysing material microstructures because they determine their properties,” says Dmitry Bulgarevich of Japan’s National Institute for Materials Science (NIMS).

Featured in Asia Research News 2020 Magazine

Materials scientists in Japan are developing a technique that recognizes and labels detailed microscopic structures inside welded steel, much like some applications tag friends in your photos. The approach could help accelerate our understanding of metal properties, while also paving the way for designing new materials.

“Metallurgists are very interested in analysing material microstructures because they determine their properties,” says Dmitry Bulgarevich of Japan’s National Institute for Materials Science (NIMS). “Most of the data for these studies comes from optical or electron microscopy imaging techniques that can produce an overwhelming amount of information.”

A team of materials scientists from NIMS and the University of Tokyo explored the use of machine learning to rapidly analyse these large amounts of data.

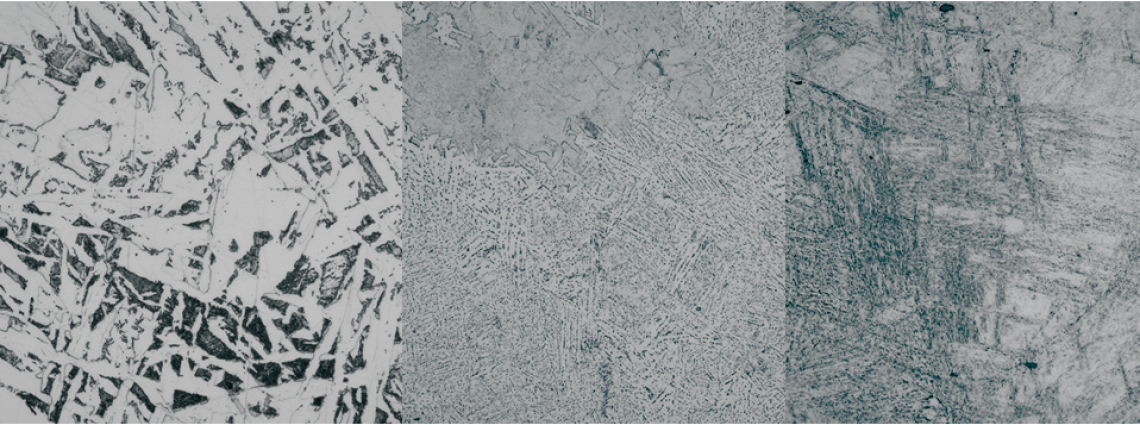

The three types of alloy microstructures identified in microscopic images. From left to right: Ferrite/Pearlite, Ferrite/Pearlite/Bainite and Bainite/Martensite.

They prepared steel alloys made from carbon, silicon, manganese, phosphorus and sulphur by cooling them from 1400°C at different rates: 0.3°C, 1°C, 3°C, or 10°C per second. The variable cooling rates led to the formation of different microstructures within the steel. Expert metallurgists manually identified three types of microstructures in microscopic images of the alloys: ferrite/pearlite, ferrite/ pearlite/bainite, and bainite/martensite. Sub-phases of ferrite were also identified.

The images were processed and then run through several machine learning models, using algorithms to train them to recognize and label the images. The team found a machine learning classification method, called Random forest, made the most accurate predictions of alloy microstructure. This method could be applied to a wide range of metals in both research and industry settings.

“There is much hope this machine learning method will assist in automating microstructure analysis using large datasets and in the development of new materials with desired mechanical properties,” Bulgarevich says.

Further information

Dmitry S. Bulgarevich | E-mail: [email protected]

Research and Services Division of Materials Data and Integrated System

National Institute for Materials Science

Shunichi Hishita | E-mail: [email protected]

Science and Technology of Advanced Materials

National Institute for Materials Science

Read this story in the Asia Research News 2020 magazine.

The many ways we can tell your research story. Find out more from our Content services page.