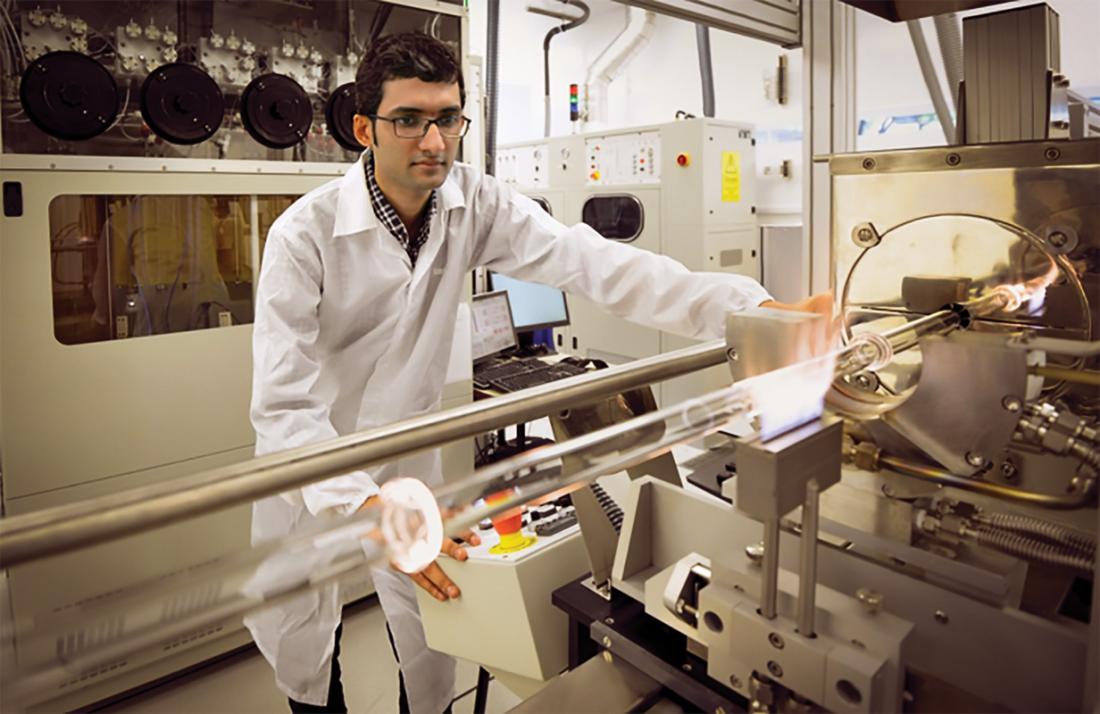

Dr Sidharthan Raghuraman works on the Modified Chemical Vapor Deposition (MCVD) system, which is used for the fabrication of optical fibre preform

Fibre optics—strands of transparent glass or plastic, thinner than a human hair—have long fascinated scientists and engineers. Extremely flexible and able to carry light over large distances, optical fibres have enabled breakthroughs in communications and data transfer. But the applications don’t stop there. The Centre for Optical Fibre Technology (COFT) in Singapore is exploring diverse ways to use optical fibres: from cancer screening and materials processing to wearable technology.

Founded in 2014, COFT is the newest of five centres, collectively dubbed The Photonics Institute, based at Singapore’s Nanyang Technological University. The institute’s main mission is to translate fundamental research about technologies based on light photons, a field known as photonics, into next-generation devices. COFT is home to Singapore’s first fibre-drawing tower, a key tool for manufacturing new fibre designs. Staff use this and other tools to fabricate the whole range of optical fibres, from passive and active silica fibres, to soft glass and polymer fibres. Having all of the necessary equipment on-site means that designs can be realized quickly and readily optimized. Take, for example, one of COFT’s early success stories: a kilowatt-class fibre laser system, built to deliver a high power optical beam, which the team developed from scratch within two years. The flexible form of a laser based on optical fibres makes it a versatile tool for robot-led industrial applications such as drilling or welding. Also, fibre lasers can be less susceptible to knocks or vibration, as the fibre integrates key laser elements, such as mirrors and amplifying material, that would otherwise need to be carefully aligned.

“Presently we are working with high power fibre laser systems operating at one and two micron wavelengths. But in the longer term we aim to cover the entire spectrum from ultraviolet to mid-infrared,” says Wenn Jing Lai, one of COFT’s three senior programme directors. The more wavelengths that are available, the wider the range of materials that can be laser-machined, which includes surface treatments as well as precision cutting. Examples include metals, plastics, glasses and also biomaterials such as teeth or bone. Now that they have a demonstration unit up and running, Lai and her colleagues are searching for industrial collaborators to explore applications in more detail. She is particularly excited about the prospects of using fibre lasers to enable additive manufacturing or 3D printing, which would open the door to rapid prototyping and custom manufacturing for a wide range of industries, from defence to medical devices.

OPTIMIZING FOR HEALTHCARE

Fibre optics are also well-suited for sensing inside the body as they can be deployed without having to make large incisions in the skin. By teaming up with clinicians, COFT researchers can engineer solutions that are well matched to patient needs. For example, a surgeon at Singapore General Hospital approached COFT about developing a fibre optic device to detect a form of pancreatic cancer called pancreatic ductal adenocarcinoma. “Right now there is almost no way to detect it at early stage development,” says Linbo Liu, who heads up the centre’s medical fibre programme. “We hope to design a fibre optic device to deliver light into the pancreas to classify cancerous lesions much earlier than is possible today.” Based on reflected light gathered at the end of a fibre inserted into the body, the team is prototyping a system to differentiate between normal tissue, low grade cancer and cancer of a higher grade. More generally, the delivery of diagnostic light through small and flexible fibres could help surgeons scan suspicious areas and locate lesions in various sites in the body, such as in the stomach, colon and oesophagus.

COMPACT COMMUNICATIONS

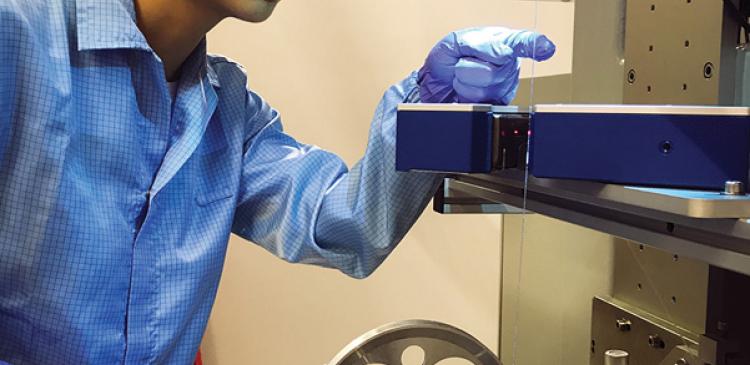

One of the most well known applications for optical fibres is telecommunications, which today involves the transmission of mind-boggling amounts of digital information around the globe. Rising demand for data-hungry services such as streaming high definition video means that developers are needing to get smarter and find new ways of increasing bandwidth. Photonics is a major enabling technology, with high speed integrated optical circuits beginning to replace slower electronic circuits at data centres. Novel optical fibres could also play a big role in supporting larger amounts of data traffic, explains Lei Wei, director of COFT. Using COFT’s suite of fabrication tools, his group is constructing ultra-compact multicore designs that feature multiple strands of optical material drawn down into a diameter no bigger than today’s single core—or single stranded—fibres. “Currently, we can successfully integrate up to seven cores—or strands— without sacrificing the thickness of the fibre,” he comments. “That means we can enlarge the data transmission capability seven-fold with a single fibre.”

FUTURISTIC FABRICS

Like all staff at the centre, Wei has a broad vision for the future of optical fibres and the possibilities that different material formats bring, which includes using fibre optics to advance wearable technology. “Commercially available wearable devices such as smart watches are typically treated as accessories,” says Wei. “They are an optional part of our daily life, but the angle we are taking is to consider them a necessary part.” His group is exploiting the textile nature of optical fibres to construct hightech clothing that can sense the wearer’s heartbeat or temperature distribution. Most recently, the scientists have been using thermoelectric fibres to generate an active cooling effect that equates to a temperature drop of around 6°C. Future products based on the concept could include air conditioning T-shirts powered by fibre-shaped batteries.

INTERNATIONAL BY DESIGN

Bringing such a wide range of projects under one US$3.6 million facility is a key part of the centre’s blueprint for success. Researchers are encouraged to collaborate with each other and partner with organizations from all over the world, such as the Lee Kong Chian School of Medicine in Singapore, Harvard Medical School in the US, the University of Southampton in the UK, and Max Plank Institutes in Germany. The centre has hosted numerous visiting scientists to join forces with its 50 or so researchers and students since opening its doors. “Today we are working with many experts in different parts of the world; collaborating with some of the best institutes in our field,” explains Perry Shum, the centre’s founding director. It’s this passion for a collaborative environment, combined with the tools enabling rapid exploration of new ideas, that is elevating COFT’s reputation as an important hub for photonics development. By innovating bespoke solutions based on optical fibres, Shum, Wei and their colleagues hope to make valuable contributions to a world increasingly transformed by photonics.

For further information, contact:

Assistant Professor Wei Lei

E-mail: [email protected]

Centre for Optical Fibre Technology

Nanyang Technological University